MODUtherm - Vertical

Modular Air Handling Units with EC fan motors.

Up to 8,040 Litres/Sec.

MODUtherm® fully integrates multiple technologies to minimise energy consumption and deliver reliable, trouble-free performance. Their modular design and construction reduces overall unit dimensions making them ideal for plant rooms with limited space. The high quality range features state-of-the-art high efficiency EC plug fans and the latest airtight casing construction.

MODUtherm’s innovative design incorporates EC fans that operate in parallel and are mounted adjacent to each other on an internal wall. The design provides inherent fan redundancy and will continue to operate even if there is a fault with one fan. The fans can be controlled by MODBUS or 0-10V signal and run independently or integrated into most building management systems.

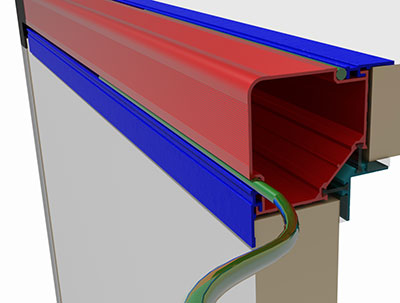

The units are constructed with 50mm thick insulated panels that are fitted with the revolutionary AHU CLIP ‘n’ LOCK fastening system. This airtight system includes a synthetic cord and aluminium capping that give the unit a strong, rigid structure and allows the panels to be removed easily for maintenance and cleaning. AHU CLIP ‘n’ LOCK also provides a high thermal performance which reduces condensation and minimises energy loss. The high quality modular casing construction achieves both the highest degree of air tightness, rating “L1”, and the highest resistance to condensation, rating “TB1”, as defined in BS EN 1886:2007.

They are also available in Horizontal or Multizone configurations.

- High quality double skin Colorbond 50mm polyurethane panel construction that complies with National Construction Code insulation specification J5.2

- Panels have zero ozone depleting potential (0% ODP)

- CLIP ‘n’ LOCK panels are easy to remove allowing access for maintenance and cleaning

- High efficiency EC plug fans with integrated speed control, current overload and motor phase protection, reverse polarity, locked rotor protection and soft starting

- EC plug fan motors exceed EU’s minimum level of efficiency for electric motors (IE4)

- To minimise on-site installation time fan motors are pre-wired to a junction box

- Chilled water cooling coils available with 3, 4, 5, 6, 8 or 10 rows and 315, 394 or 472 fins per metre

- Hot water heating coils available with 1 or 2 rows and 315, 394 or 472 fins per metre

- Combined maximum of 10 cooling and heating coil rows per unit

- Cooling and heating coil separation with access door

- Matching filter plenums are available

- Upper and lower condensate tray manufactured from quality 304 grade stainless steel (316 grade stainlesssteel option also available)

- Shopping centres

- Office buildings

- Hotels

- Health facilities

- Schools and Universities

Units incorporate the unique CLIP ‘n’ LOCK system where the removable casing panels clip into a continuous aluminium locking strip with an EPDM closed cell foam underseal. The locking strip is secured into position with a continuous synthetic cord, forming an airtight seal. MODUtherm units include a modular, thermally broken aluminium frame construction with double skin, 50mm thick polyurethane-filled panels. The unit case has a TB1 thermal bridging and Class L1 leakage rating. Casing construction complies with National Construction Code insulation specification J5.2 (all areas except for alpine areas).

Each unit is complete with a lift-off access panel on the coil pipe side allowing for inspection and cleaning. Access to the fan section and filter plenum is by hinged door. The upper and lower condensate trays are of a non-ponding design manufactured from grade 304 stainless steel.

Units incorporate multiple, high efficiency EC plug type fans operating in parallel and mounted adjacent to each other on an internal wall. The number of fans varies depending on the model.

- EC motors are 3 phase 415V 50-60Hz

- Bearings are sealed for life ball type

- Integrated EC controller provides infinite speed control

- IP54-rated

Integral thermal overload protection is supplied as standard.

Protection will not prevent fans from functioning in fire mode as required by AS/NZS1668.1:2015.

The Air Handling Units shall be of the MODUtherm® series as designed by Fantech and be of the model numbers as shown on the schedule/drawing.

Units shall incorporate modular, thermally broken, aluminium frame construction with double skin, 50mm thick, polyurethane-filled panels achieving TB1 thermal bridging rating as defined in BS EN 1886:2007. Casing shall be leakage tested to BS EN 1886, Class L1 at 100Pa positive pressure. Panels shall also comply with the National Construction Code insulation specification J5.2 and have zero ozone depleting potential (0 % ODP).

Unit casings shall incorporate CLIP ‘n’ LOCK removable panels that are sealed airtight by the use of a continuous EPDM closed cell foam underseal and a continuous clip in aluminium locking strip. The panels are locked into the strip with a continuous synthetic cord. The panels shall be removable without the need for screws or fasteners to allow access for maintenance. Cooling and heating capacities and external static pressures shall be as shown on the schedule.

Units shall incorporate multiple EC plug fans operating in parallel with motors exceeding EU’s minimum efficiency level (IE4) and complying with IP54 protection. Fans shall be pre-wired to an external terminal box.

Models *

| Model Number |

Air Flow Litres/sec |

Static Pressure (External) Pa |

Cooling Capacity (Total) kW |

Cooling Capacity (Sensible) kW |

Heating Capacity (Total) kW |

Motor Power kW |

Full Load Current Amps |

Drawing |

|---|---|---|---|---|---|---|---|---|

| MODU0202V | 597 | 450 | 17.30 | 11.40 | 11.80 | 0.80 x 1 | 3.70 x 1 | MODU0202V |

| MODU0203V | 984 | 450 | 30.50 | 19.70 | 21.10 | 2.50 x 1 | 3.80 x 1 | MODU0203V |

| MODU0204V | 1372 | 450 | 42.30 | 27.40 | 30.30 | 2.40 x 1 | 3.70 x 1 | MODU0204V |

| MODU0303V | 1600 | 450 | 49.50 | 32.00 | 34.40 | 2.40 x 1 | 3.70 x 1 | MODU0303V |

| MODU0205V | 1759 | 450 | 53.60 | 34.90 | 39.40 | 2.40 x 1 | 3.70 x 1 | MODU0205V |

| MODU0304V | 2230 | 450 | 68.70 | 44.50 | 49.20 | 5.40 x 1 | 8.20 x 1 | MODU0304V |

| MODU0305V | 2860 | 450 | 87.20 | 56.70 | 60.30 | 5.40 x 1 | 8.20 x 1 | MODU0305V |

| MODU0404V | 3086 | 450 | 95.00 | 61.60 | 68.10 | 5.00 x 1 | 7.70 x 1 | MODU0404V |

| MODU0405V | 3958 | 450 | 20.60 | 78.40 | 88.60 | 5.40 x 2 | 8.20 x 2 | MODU0405V |

| MODU0307V | 4116 | 450 | 125.40 | 81.60 | 90.80 | 5.40 x 2 | 8.20 x 2 | MODU0307V |

| MODU0406V | 4829 | 450 | 131.70 | 97.70 | 103.40 | 5.40 x 2 | 8.20 x 2 | MODU0406V |

| MODU0505V | 4841 | 450 | 147.50 | 95.90 | 102.10 | 5.40 x 3 | 8.20 x 3 | MODU0505V |

| MODU0407V | 5701 | 450 | 173.70 | 113.00 | 125.80 | 5.00 x 2 | 7.60 x 2 | MODU0407V |

| MODU0506V | 5907 | 450 | 176.30 | 115.40 | 126.50 | 5.00 x 2 | 7.60 x 2 | MODU0506V |

| MODU0408V | 6572 | 450 | 203.40 | 131.60 | 145.00 | 5.00 x 2 | 7.60 x 2 | MODU0408V |

| MODU0507V | 6973 | 450 | 208.10 | 136.20 | 149.30 | 5.40 x 3 | 8.20 x 3 | MODU0507V |

| MODU0508V | 8039 | 450 | 248.80 | 161.00 | 177.40 | 5.40 x 4 | 8.20 x 4 | MODU0508V |