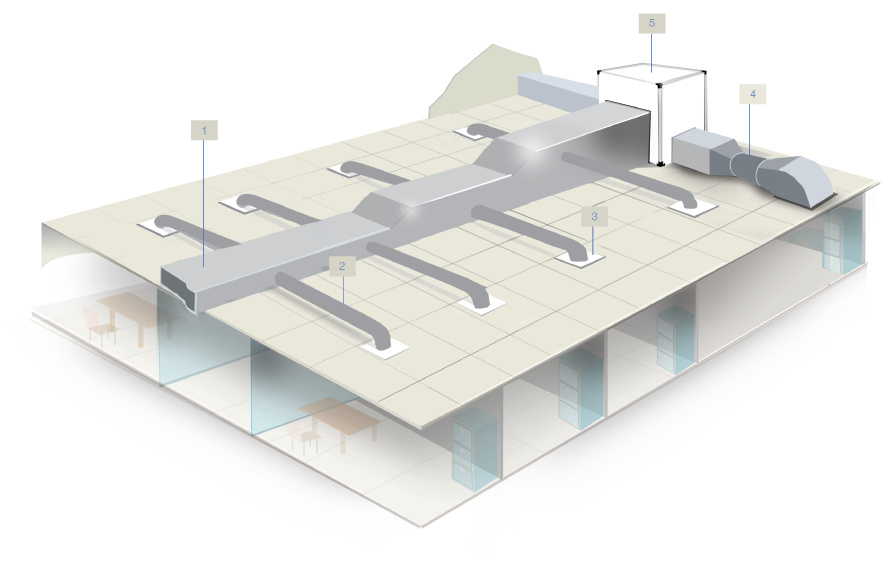

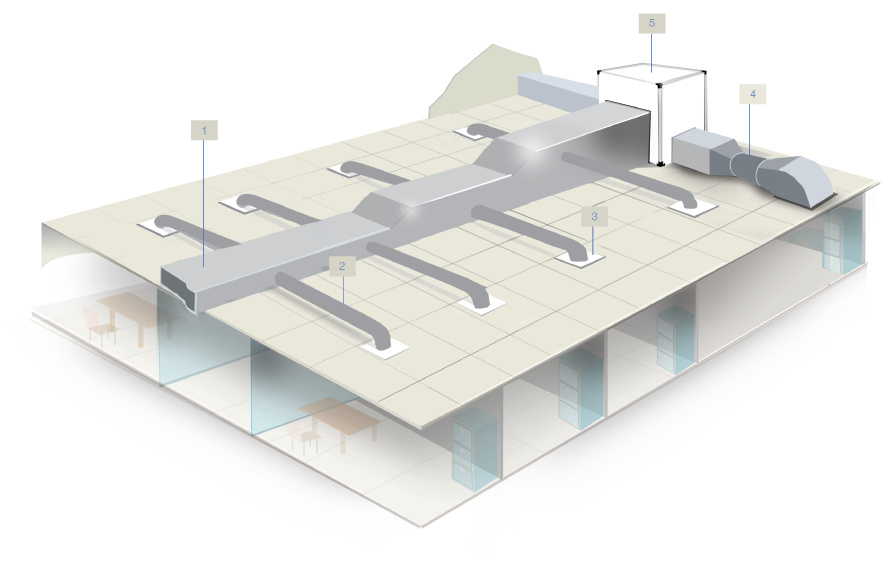

using an Air Design Air Handling Unit and Even Pressure Duct Design.

2. Branch duct length ≤ 1.5m

4. Return air Fantech axial fan

5. Air Design Air Handling Unit or Fan Coil with EC fans

AirLink is a new and more flexible Variable Air Volume (VAV) system that integrates multiple technologies including Air Design Air Handling Units and Even Pressure Duct Design. It is helping consultants and contractors take the next step in HVAC system efficiency, whilst having the potential to save capital costs.

For the past 30 years VAV systems have been the preferred air distribution method. Traditionally these have incorporated an Air Handling Unit or Fan Coil Unit with AC fans. These units are connected to a high-pressure duct network that delivers air through an inefficient VAV box with a fixed geometry diffuser. More recently EC fans have helped to improve the energy efficiency, but the system remains only moderately efficient and is limited in that it cannot be adapted to system layout changes and has the potential for noise issues.

The AirLink VAV System minimises energy consumption and can provide capital savings in almost all HVAC system designs. AirLink delivers a more efficient, more adaptive air distribution solution to help create a healthier, more comfortable indoor space. This flexible VAV system is capable of precise air delivery to every room. AirLink is also easy to re-zone and changes to the system layout can be made quickly if required.

Air Handling Unit or Fan Coil Unit with AC fans connected to a high pressure duct network that delivers air through an inefficient VAV box with a fixed geometry diffuser

Potential resultAir Handling Unit or Fan Coil Unit with EC fans mismatched to a high pressure duct network that delivers air through an inefficient VAV box with a fixed geometry diffuser.

Potential resultAir Handling Unit or Fan Coil Unit with EC fans matched to an efficient low pressure duct network that delivers air through an intelligent electronically controlled VAV diffuser.

Potential resultAn AirLink VAV system combines Even Pressure Duct Design, electronic VAV diffusers and Air Handling Units/Fan Coil Units with EC fans, to achieve capital savings in almost all building types. Independent analysis that supports this has been produced based on a range of different building types in Australia.

In addition to the initial capital savings, Air Design’s AHUs and FCUs can provide lower “lifetime” costs. Their fully integrated and compact EC fans are faster and easier to replace than traditional DWDI fans. This can potentially eliminate the need for cranes or gantries and reduce on-site labour costs.

Capital Cost Comparison

The AirLink Integrated VAV System is very effective in applications where the occupancy level and conditions vary throughout the day. The ventilation rate automatically adjusts to meet the changing requirements of the area; this minimises energy consumption and helps to maintain a healthy and productive indoor environment.

The extensive range of sizes for each component make the AirLink VAV system suitable for a vast range of commercial buildings, including schools and universities, hospitals, convention centres and office blocks.

The Air Design Air Handling Units and Fan Coil Units featured in this website are a critical component of the Fantech AirLink VAV system. The AirLink system combines Fantech axial fans with VSDs, Rickard VAV diffusers, the Air Design range and Even Pressure Duct Design.

The extensive range of Fantech Adjustable Pitch Axial fans is an essential part of the integrated AirLink system. Their high performance impeller blade harnesses the latest construction and design technologies to deliver enhanced pressure development, energy efficiency and reduced noise levels.

They are available in sizes ranging from 315 to 2000mm diameter and feature an adjustable pitch impeller that ensures the precise air flow and static pressure requirements of the application are delivered.

Fantech axial fans can also be supplied with Danfoss variable speed drives, providing variation of fan speed and therefore air flow volume. They can be pre-configured with parameters for specific applications to maximise energy efficiency and improve controllability.

The Rickard Electronic VAV Diffuser range is an intelligent modular system that is zoned into independently controlled comfort areas. The system can be centrally monitored and tuned from the one location via a BMS, as well as adjusted within the occupied space. It can be used in most building types and sizes due to the simplicity of its design and flexibility of the system software.

The objective of Even Pressure Duct Design is to achieve the same static pressure throughout the duct run. This means the duct design must have an even static pressure from the first diffuser take off. Any duct design method can be adopted for the main supply air duct.

The static pressure should be the same before every VAV diffuser and at each branch. The pressure at each diffuser does not need to be perfectly even as the VAV diffuser can manage a ∓10% tolerance with ease.